IoT industrial solutions provider and their impact

IoT industrial solutions provider takes center stage as industries increasingly turn to the Internet of Things to revolutionize their operations. With the ability to connect devices and gather data, businesses can optimize processes and improve efficiency. Understanding the nuances of these solutions is essential for any organization looking to stay competitive in the modern landscape.

From enhancing predictive maintenance to streamlining logistics, IoT solutions are transforming how industries operate. By leveraging data analytics and integrating advanced technologies, companies can gain insights that drive informed decision-making. The significance of choosing the right IoT industrial solutions provider cannot be overstated, as it directly influences the success of these initiatives.

Understanding IoT Industrial Solutions

The Internet of Things (IoT) has transformed the landscape of industrial solutions, integrating smart technology into industrial operations. This evolution has bolstered efficiency, enhanced decision-making, and increased productivity across various sectors. IoT industrial solutions involve the interconnection of machinery and devices, enabling seamless communication and data exchange, which are pivotal in modern manufacturing and production processes.Key components of IoT solutions in an industrial context include devices, connectivity, data processing, and analytics.

Each component plays a crucial role in ensuring that systems operate cohesively and effectively. Devices such as sensors and actuators collect real-time data, while connectivity options, including Wi-Fi, LTE, or LPWAN, facilitate the transmission of this data to processing units. Data processing involves analyzing the collected data to derive meaningful insights, and analytics tools help in making informed decisions based on this data.

Key Components of IoT Solutions

In an industrial setting, understanding the key components of IoT solutions is essential for leveraging their full potential. The following aspects are critical:

- Devices and Sensors: These are the backbone of IoT, as they gather vital information from various operational environments, such as temperature, pressure, and machine performance.

- Connectivity: Ensuring that devices can communicate effectively using protocols like MQTT and HTTP is crucial. This connectivity can be achieved through various means, including wired and wireless technologies.

- Data Processing: This component involves the analysis of data collected from devices. It can occur on the cloud or on-premises, depending on the specific needs of the industrial operation.

- Analytics and Visualization: Advanced analytics tools are utilized to interpret the processed data, providing insights through dashboards and visualizations that aid in decision-making.

- Security: Protecting data integrity and ensuring secure communication channels is paramount in IoT solutions to prevent unauthorized access and data breaches.

The adoption of IoT technologies in industrial operations brings a multitude of benefits. By integrating these solutions, businesses can optimize their processes and reduce operational costs.

Benefits of Adopting IoT Technologies

The advantages of implementing IoT technologies in industrial settings are numerous and impactful. Some notable benefits include:

- Enhanced Operational Efficiency: IoT enables real-time monitoring and automation of processes, significantly improving efficiency and reducing downtime.

- Predictive Maintenance: By leveraging data analytics, companies can predict equipment failures before they occur, minimizing disruptions and reducing maintenance costs.

- Improved Quality Control: Continuous monitoring allows for immediate identification of anomalies, thus maintaining product quality and compliance with industry standards.

- Data-Driven Decision Making: The insights gained from IoT enable better strategic decisions, aligning operations with market demands and improving overall competitiveness.

- Supply Chain Optimization: IoT solutions facilitate better inventory management and logistics, leading to streamlined operations and reduced costs.

Implementing IoT industrial solutions not only enhances productivity but also fosters innovation, driving businesses towards future advancements in technology and efficiency.

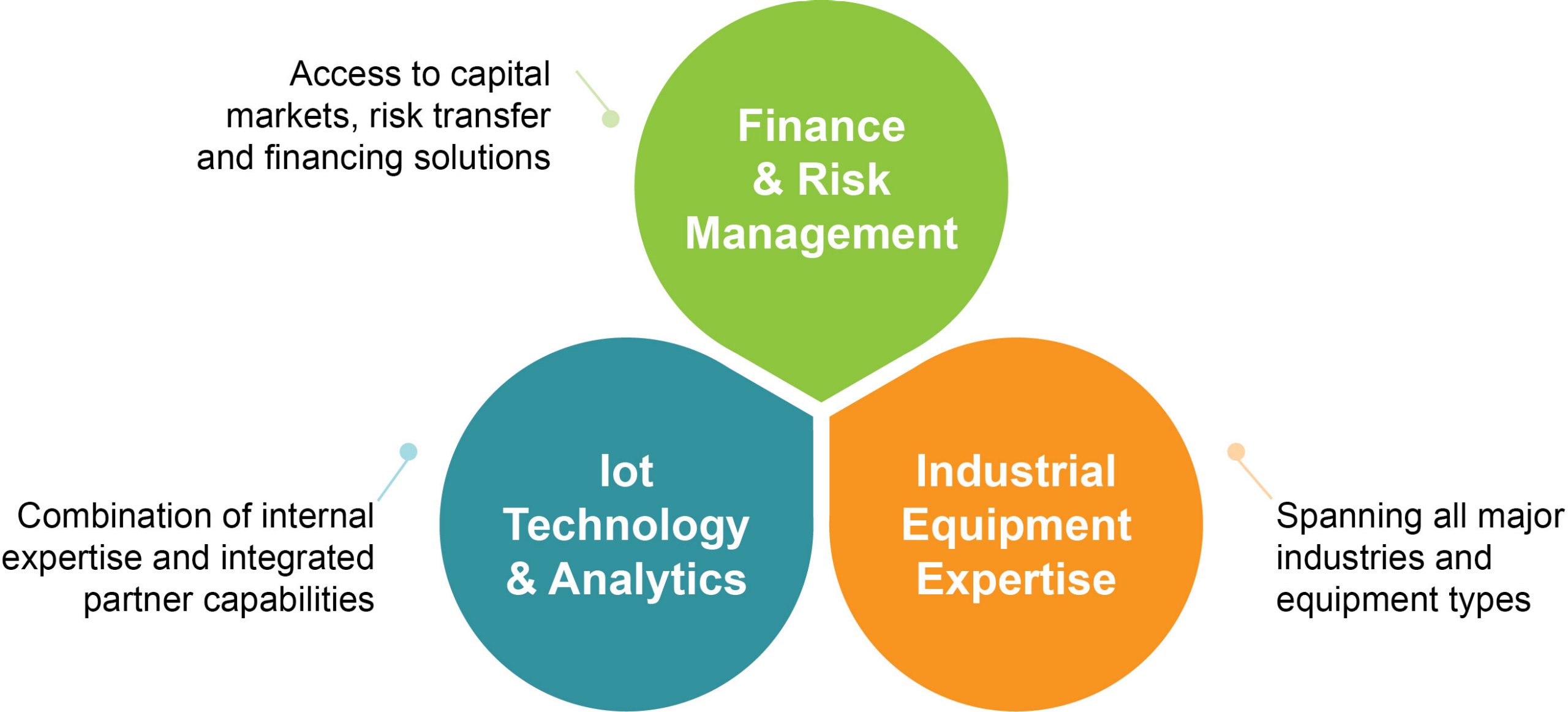

Key Features of IoT Industrial Solutions Providers

In the evolving landscape of industrial automation, selecting a reliable IoT solutions provider is crucial for businesses seeking to enhance efficiency and streamline operations. A dependable provider not only offers innovative technology but also integrates essential features that ensure robust performance, security, and scalability in IoT applications. Understanding these key attributes can significantly influence the effectiveness of an organization’s IoT strategy.

Essential Features of IoT Industrial Solutions

A reliable IoT industrial solutions provider should incorporate several fundamental features that enable organizations to achieve their operational objectives. These features include:

- Interoperability: The ability to seamlessly connect various devices and systems, ensuring that different technologies can work together effectively.

- Real-time Data Analytics: Providers should offer advanced analytics capabilities that allow organizations to make data-driven decisions quickly, enhancing operational responsiveness.

- Customizability: Solutions should be tailored to meet specific industry needs, allowing businesses to adapt the technology to their unique processes and workflows.

- User-friendly Interfaces: Intuitive dashboards and control panels simplify monitoring and management, making it easier for staff at all levels to engage with the technology.

Role of Scalability in IoT Solutions

Scalability is a significant aspect of IoT solutions, allowing organizations to grow their IoT deployments without encountering major hurdles. A robust IoT provider ensures scalability by:

- Modular Architecture: By utilizing a modular system design, businesses can add additional devices and functionalities as needed, avoiding large-scale overhauls.

- Cloud Integration: Cloud-based services enable providers to offer flexible, scalable resources that adapt to changing data volumes and processing needs.

- Performance Monitoring: Continuous assessment of system performance ensures that scalability challenges are identified early, allowing proactive adjustments and upgrades.

Importance of Security Measures

Security is a paramount concern for IoT industrial solutions, given the sensitive nature of the data involved. A trustworthy provider implements comprehensive security measures to protect against potential vulnerabilities. This includes:

- Data Encryption: Encrypting data in transit and at rest ensures that sensitive information remains confidential and secure from unauthorized access.

- Regular Security Audits: Conducting frequent assessments and updates to identify and address potential security flaws in the system architecture.

- Access Control: Implementing robust authentication protocols to restrict access to authorized personnel only, reducing the risk of internal and external threats.

Industry Applications of IoT Solutions

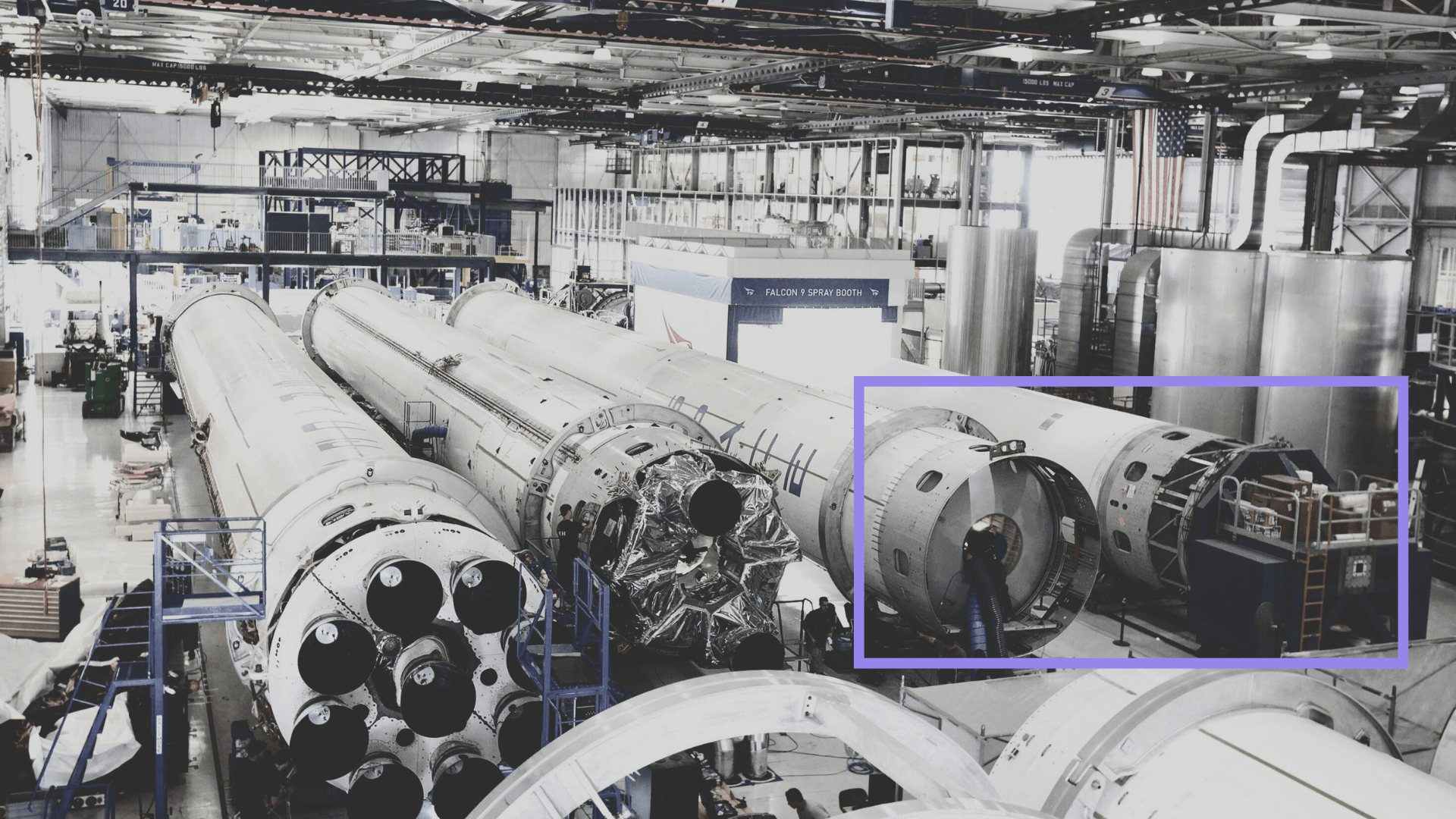

The Internet of Things (IoT) is revolutionizing various industries by enhancing operational efficiency and enabling smarter decision-making processes. In sectors such as manufacturing, logistics, and energy, IoT solutions are providing significant advancements that contribute to streamlined operations, reduced costs, and increased productivity.IoT solutions leverage interconnected devices and real-time data to optimize processes, improve resource management, and ensure higher levels of automation.

By embedding sensors and communication technologies into machinery and equipment, organizations can monitor performance, gather insights, and predict potential issues before they escalate.

Manufacturing Sector

The manufacturing industry is one of the leading adopters of IoT technologies. Smart factories utilize IoT solutions to create interconnected systems that enhance productivity and reduce waste. These are key benefits of IoT in manufacturing:

- Real-time Monitoring: Sensors track machine performance and environmental conditions, allowing for immediate adjustments to optimize production lines.

- Predictive Maintenance: IoT solutions enable the analysis of machinery usage patterns, predicting when maintenance is needed and minimizing unexpected downtime.

- Quality Control: Automated systems can detect defects during production, ensuring high-quality standards and reducing rework or scrap rates.

The implementation of IoT in manufacturing has led to a notable decrease in production costs and an increase in output. For example, General Electric has reported significant improvements in operational efficiency due to its Predix platform, which offers analytics and insights for industrial operations.

Logistics and Supply Chain Management

In logistics, IoT solutions are crucial for enhancing supply chain visibility and efficiency. Connected devices facilitate real-time tracking of goods, allowing for better inventory management and route optimization.The advantages of IoT in logistics include:

- Asset Tracking: RFID tags and GPS enable real-time tracking of shipments, reducing losses and improving delivery times.

- Condition Monitoring: Sensors can monitor the condition of sensitive goods in transit, alerting stakeholders of temperature fluctuations or damage.

- Operational Insights: Data collected from devices can be analyzed to identify bottlenecks and optimize routes for cost-efficiency.

Companies like Amazon utilize IoT technologies to streamline their logistics operations, improving customer satisfaction through timely deliveries and accurate tracking.

Energy Sector

The energy industry is leveraging IoT solutions to promote sustainability and optimize resource consumption. Smart grids and connected devices aid in managing energy distribution more effectively.Key impacts of IoT in the energy sector include:

- Demand Response: IoT enables utilities to monitor energy usage in real-time, allowing them to adjust supply based on consumption patterns and reduce peak demand.

- Predictive Maintenance: Sensors on equipment like turbines and transformers allow for predictive analytics, which helps in maintaining optimal operational levels and minimizing downtime.

- Renewable Energy Integration: IoT solutions facilitate the integration of renewable energy sources, adjusting energy storage and distribution dynamically based on availability.

For instance, companies like Siemens have utilized IoT technologies to enhance their energy management systems, leading to significant savings and improved sustainability practices.

The integration of IoT solutions in these industries not only enhances efficiency but also paves the way for innovative practices that reshape how businesses operate.

Choosing the Right IoT Industrial Solutions Provider

Selecting an appropriate IoT industrial solutions provider is pivotal for ensuring your business reaps the maximum benefits from IoT technology. With a plethora of options available, businesses must be diligent in evaluating potential partners to find the best fit for their unique requirements. The right provider can significantly enhance operational efficiency, streamline processes, and ultimately contribute to a more profitable enterprise.To effectively assess which provider aligns with your needs, consider a comprehensive checklist of criteria that encompasses essential aspects of their offerings, reputation, and support capabilities.

Evaluation Criteria for IoT Solutions Providers

When evaluating potential IoT solutions providers, it’s important to adopt a structured approach. Here are key criteria to consider:

- Industry Expertise: Providers with a strong track record in your specific industry can better understand your unique challenges and requirements.

- Technology Compatibility: Assess whether their solutions integrate well with your existing systems and technologies.

- Scalability: Ensure the provider can accommodate growth and changes in your operations smoothly without significant disruptions.

- Security Measures: Evaluate the robust security protocols in place to protect sensitive data.

- Cost Structure: Understand their pricing models and how they align with your budget and expected ROI.

- Customer Support: Comprehensive support services are essential for troubleshooting and ongoing maintenance.

Models of Service Delivery in IoT Solutions

Different IoT solutions providers offer various models of service delivery, each with distinct benefits and drawbacks. Here’s a breakdown of common models:

- Software as a Service (SaaS): This model allows businesses to access IoT applications via the cloud, minimizing the need for on-premise infrastructure and providing flexibility in scaling.

- On-Premise Solutions: These require local installation of software and hardware, providing greater control over data and security but typically at higher initial costs.

- Hybrid Solutions: Combining both cloud and on-premise capabilities, hybrid solutions offer flexibility and can be tailored to specific operational needs.

Each model has its pros and cons, and the choice largely depends on your organization’s specific requirements, existing infrastructure, and long-term strategic goals.

Importance of Customer Support and Training

Customer support and training play a crucial role in the successful implementation and ongoing use of IoT solutions. A provider that offers robust support services can ensure that technical issues are addressed promptly, minimizing downtime. Moreover, comprehensive training for staff is essential for maximizing the effectiveness of IoT technologies. Many organizations struggle with technology adoption due to inadequate training, which can lead to underutilization of the solutions.

Thus, when selecting an IoT solutions provider, prioritize those that offer:

- 24/7 Technical Support: Immediate assistance is vital for resolving issues that may arise unexpectedly.

- Comprehensive Training Programs: Both initial and ongoing training to keep staff updated on new features and enhancements.

- User-Friendly Documentation: Accessible guides and resources that enable users to troubleshoot and optimize their use of the technology.

A strong support system ultimately enhances user experience and ensures that your organization remains agile and competitive in an ever-evolving industrial landscape.

Case Studies of Successful IoT Implementations

The integration of Internet of Things (IoT) technologies in various industries has brought about transformative changes, enhancing efficiency, productivity, and decision-making processes. This section delves into specific case studies that illustrate the successful deployment of IoT solutions across different sectors. Each example will highlight the challenges faced during implementation and the measurable outcomes achieved through these innovative technologies.

Manufacturing: Smart Factory Implementation

In the manufacturing sector, the implementation of IoT has led to the creation of smart factories, where machinery, systems, and human operators are interconnected. A notable case is that of Siemens, which introduced IoT technology in its Amberg facility in Germany. The challenge was integrating legacy systems with new IoT solutions while maintaining operational continuity. To overcome this, Siemens invested in a robust IoT platform that allowed for seamless data flow and real-time monitoring.

The smart factory now boasts a production efficiency increase of 30%, with a significant reduction in downtime due to predictive maintenance models. The return on investment (ROI) has been substantial, with the company reporting cost savings of millions annually due to optimized operations.

Energy Sector: Smart Grid Solutions

The energy sector has also witnessed successful IoT implementations, particularly with smart grid technologies. A prominent example is the project undertaken by Pacific Gas and Electric (PG&E) in California. The challenge involved the need for real-time data collection to improve grid reliability and reduce energy waste.PG&E deployed smart meters equipped with IoT capabilities that provided instant feedback on energy usage patterns.

This initiative not only enhanced service reliability but also empowered customers to manage their consumption more effectively, leading to energy savings of 10-15% on average.The measurable outcome included a 20% reduction in outage response time, translating into substantial cost savings and improved customer satisfaction.

Healthcare: Remote Patient Monitoring

In healthcare, IoT technologies have revolutionized patient care through remote monitoring solutions. A case study involving Philips Healthcare highlights the deployment of IoT devices for chronic disease management. The main challenge was ensuring data security and privacy while utilizing connected devices.Philips addressed this by employing advanced encryption methods and compliance with healthcare regulations. The outcome was the successful monitoring of patients’ health metrics in real-time, which reduced hospital readmission rates by 25%.

The ROI for healthcare providers was evident as operational costs decreased, and patient outcomes improved significantly, showcasing the effectiveness of IoT in enhancing healthcare delivery.

Logistics: Fleet Management Optimization, IoT industrial solutions provider

Logistics and supply chain management have greatly benefited from IoT solutions, particularly in fleet management. A case study of DHL illustrates the successful implementation of IoT tracking systems for their delivery vehicles.One of the challenges faced was real-time tracking of vehicle conditions and optimizing route efficiency. DHL introduced IoT sensors to monitor vehicle performance and traffic conditions. As a result, they achieved a 15% decrease in fuel consumption and improved delivery times by 20%.The measurable outcomes included significant cost reductions in fuel expenditures and increased customer satisfaction due to timely deliveries, demonstrating the impact of IoT in logistics.

Agriculture: Precision Farming

In the agricultural sector, precision farming is a compelling example of IoT implementation. A case study focused on John Deere illustrates how IoT technology was utilized to enhance crop yield and resource management. The challenge revolved around gathering accurate field data for timely decision-making.John Deere’s solution involved deploying IoT sensors throughout fields to monitor soil conditions, moisture levels, and crop health.

This enabled farmers to apply water and fertilizers more efficiently, resulting in a 20% increase in crop yield while reducing water usage by 30%.The ROI from these IoT solutions has been evident in enhanced productivity and sustainability in farming practices, providing a compelling argument for the adoption of IoT in agriculture.

Future Trends in IoT Industrial Solutions

The future of IoT industrial solutions is poised for transformative changes, driven by advancements in technology and evolving industry needs. As the world becomes increasingly interconnected, IoT solutions are integrating new capabilities that enhance operational efficiency, data management, and automation processes. This segment explores the emerging trends shaping the landscape of IoT industrial solutions and highlights the significant role of artificial intelligence and data analytics in this evolution.

Emerging Trends in IoT Technology

Several key trends are emerging in the IoT industrial landscape that are set to redefine how industries operate. These trends include:

- Edge Computing: This trend reduces latency by processing data closer to the source, enabling faster decision-making and real-time analytics.

- 5G Connectivity: The rollout of 5G networks enhances connectivity, allowing for higher data transfer speeds and more devices to be connected, which is crucial for industrial applications.

- Interoperability Standards: The push for standardized protocols facilitates seamless integration of various IoT devices, promoting compatibility and ease of use across different platforms.

- Cybersecurity Enhancements: As IoT devices proliferate, robust cybersecurity measures are becoming essential to protect industrial systems from potential breaches and threats.

- Sustainability Initiatives: IoT solutions are increasingly focused on reducing environmental impact through efficient resource management and energy monitoring, aligning with global sustainability goals.

Impact of Artificial Intelligence on IoT Industrial Applications

Artificial intelligence (AI) is revolutionizing IoT applications in industrial settings by enabling smarter data processing and analysis. The integration of AI into IoT solutions allows for predictive maintenance, where machine learning algorithms analyze data from equipment to predict failures before they occur. This not only minimizes downtime but also reduces maintenance costs.

“The combination of AI and IoT can lead to significant improvements in operational efficiency and productivity.”

AI also enhances automation processes by enabling systems to learn from historical data and optimize operations in real-time. For instance, AI algorithms can dynamically adjust manufacturing processes based on changing conditions, improving quality control and reducing waste.

Role of Data Analytics in the Evolution of IoT Solutions

Data analytics plays a crucial role in the advancement of IoT industrial solutions by transforming raw data into actionable insights. As IoT devices generate massive amounts of data, robust analytics tools are required to harness this information effectively. The importance of data analytics in IoT can be summarized through the following points:

- Real-time Monitoring: Analytics platforms can process data in real-time, allowing for immediate responses to anomalies detected across various industrial processes.

- Informed Decision Making: By analyzing trends and historical data, organizations can make data-driven decisions that enhance productivity and operational efficiency.

- Enhanced Customer Insights: Data analytics provides insights into customer behavior and preferences, enabling businesses to tailor their offerings and improve service delivery.

- Resource Optimization: Analytics identifies inefficiencies in resource use, allowing companies to optimize inventory levels, reduce waste, and manage energy consumption more effectively.

The future of IoT industrial solutions is bright, with technology continuously evolving to meet the ever-changing needs of various industries. As we embrace these trends, the interplay of AI and data analytics will be critical in driving innovation and unlocking the full potential of IoT capabilities.

Challenges and Risks in Implementing IoT Solutions: IoT Industrial Solutions Provider

Adopting Internet of Things (IoT) technologies can unlock significant opportunities for businesses, but it also comes with its fair share of challenges and risks. As organizations delve into IoT implementations, understanding these hurdles is crucial to harnessing the full potential of these innovative solutions. Implementing IoT solutions often encounters various obstacles that can hinder the desired outcomes. These challenges range from technical issues to organizational resistance and regulatory concerns, all of which require careful consideration.

Common Challenges in IoT Implementation

A number of challenges can arise during the adoption of IoT technologies, including:

- Integration with Legacy Systems: Many businesses rely on established systems that may not be compatible with new IoT solutions. This integration can require significant modifications and investments.

- Interoperability: The lack of standard protocols can make it difficult for different IoT devices and platforms to communicate effectively, leading to siloed data and inefficient operations.

- Scalability: As companies expand their IoT initiatives, they may struggle to scale their infrastructure and resources adequately to manage the growing number of devices and data.

- Cost Management: The initial investment in IoT technology, along with ongoing maintenance and operational costs, can be a barrier for many organizations.

- Skills Gap: Finding talent with the right skill set to manage and analyze IoT data is often a challenge, leading to potential delays in project implementation.

Data Privacy and Management Risks

With the proliferation of IoT devices, data privacy and management risks become paramount. Organizations must be vigilant about how they handle sensitive information collected from these devices.Key risks associated with data privacy in IoT include:

- Unauthorized Access: Devices may be vulnerable to cyberattacks, allowing malicious actors to gain access to sensitive data and systems.

- Data Breaches: Inadequate security measures can lead to breaches, resulting in loss of customer trust and potential legal ramifications.

- Compliance Issues: Organizations must adhere to various regulations regarding data protection, which can vary by industry and region, complicating compliance efforts.

“The risk of data breaches in IoT has increased, with an estimated 98% of IoT devices vulnerable to cyber threats.”

Strategies for Mitigating Risks

To effectively navigate the challenges and mitigate risks associated with IoT implementations, businesses can adopt several strategies, such as:

- Implementing Robust Security Protocols: Utilizing encryption, secure authentication, and regular software updates can fortify device security against unauthorized access.

- Conducting Risk Assessments: Regularly evaluating the potential risks involved in IoT systems will help in identifying vulnerabilities and developing contingency plans.

- Training and Educating Employees: Equipping staff with knowledge about IoT security best practices can reduce the risk of human error leading to security breaches.

- Establishing Clear Data Governance Policies: Organizations should define how data will be collected, stored, and managed to ensure compliance with regulatory requirements and protect user privacy.

- Choosing Reputable IoT Vendors: Partnering with trusted IoT solution providers can ensure that security measures are built into the hardware and software from the ground up.

Integrating IoT with Other Technologies

The integration of IoT with other advanced technologies is pivotal for enhancing operational efficiency and driving innovation in the industrial sector. Synergizing IoT with technologies like artificial intelligence (AI), blockchain, and big data creates a robust ecosystem that empowers organizations to derive actionable insights, ensure data integrity, and optimize processes.The convergence of these technologies results in a comprehensive solution that addresses the complexities of modern industrial environments.

For example, AI algorithms can analyze real-time data from IoT devices, facilitating predictive maintenance and reducing downtime. Blockchain technology enhances security and traceability, ensuring that data from IoT devices is immutable and trustworthy. Big data analytics, on the other hand, allows organizations to process vast amounts of information generated by IoT devices, leading to informed decision-making.

Methods for Integrating IoT Solutions with Existing Industrial Systems

Integrating IoT solutions into pre-existing industrial systems requires strategic planning and careful execution. Here are some effective methods for achieving seamless integration:

- API Utilization: Leveraging Application Programming Interfaces (APIs) allows different systems to communicate and share data efficiently, ensuring interoperability between IoT solutions and legacy systems.

- Middleware Solutions: Implementing middleware can bridge the gap between IoT devices and existing software, translating data formats and protocols for smooth interaction.

- Edge Computing: By processing data closer to the source, edge computing minimizes latency and bandwidth usage, simplifying the integration of IoT devices with existing infrastructure.

- Modular Architecture: Designing systems with a modular approach ensures that new IoT components can be added or upgraded without overhauling the entire system, enhancing flexibility.

Framework for Ensuring Interoperability Among Diverse IoT Devices

Establishing interoperability among diverse IoT devices is essential for maximizing their potential and ensuring seamless communication. A structured framework can help achieve this goal:

1. Standardization of Protocols

Adopting widely accepted communication protocols, such as MQTT or CoAP, helps ensure that different devices can exchange information without compatibility issues.

2. Data Format Consistency

Utilizing common data formats like JSON or XML allows for a uniform understanding of data across various devices, enhancing communication and processing.

3. Device Discovery Mechanisms

Implementing robust discovery protocols enables devices to identify and authenticate each other within the network, facilitating smooth integration.

4. Centralized Management Platforms

Utilizing a centralized platform for device management allows for streamlined updates, monitoring, and configuration of IoT devices, ensuring all components function cohesively.

5. Security Infrastructure

Establishing a comprehensive security framework that includes encryption and authentication safeguards the integrity of data exchange among diverse devices.By following these guidelines, organizations can create a cohesive IoT ecosystem that enhances operational efficiency, reduces costs, and encourages innovation across their industrial processes.

Frequently Asked Questions

What are the main benefits of IoT industrial solutions?

The primary benefits include improved operational efficiency, reduced downtime, and enhanced decision-making through data analytics.

How do I choose the right IoT solutions provider?

Evaluate providers based on their scalability, security measures, customer support, and technology integration capabilities.

What industries can benefit from IoT solutions?

Industries such as manufacturing, logistics, energy, and healthcare can significantly enhance their operations using IoT technologies.

What role does data security play in IoT?

Data security is crucial as it protects sensitive information from breaches and helps maintain trust among users and stakeholders.

How does IoT enable predictive maintenance?

IoT devices collect real-time data that predicts equipment failures, allowing for proactive maintenance and reduced operational interruptions.